Midmark Error: E001

Error code E001 is a power interruption error. It is possible the unit is plugged into a faulty outlet, make sure that the unit is not plugged into a G.F.I. If the outlet you are plugged into is good it is possible you have a power failure at some point, try running a cycle. If the unit is giving you an E001 during or right after running a cycle it is an indication that the unit is overheating, in which case you will need to get the unit serviced.

Midmark Error: E002

ERROR CODE C983: HEATUP Midmark M9 & M11 Error Code C983 (HEATUP) The Error Code 'C983 (HEATUP)' means the High-Limit Thermostat is open.

Error code E002 is an indication that the stop button got pressed during a cycle. Make sure none of your staff touches the stop button during a cycle. If you are getting an E002 with nothing touching the stop button it is possible you have a faulty display board that may need replacing.

- Refer to the Midmark “Limited Warranty” printed in the Installation and Operation Manual for warranty informa-tion. Failure to follow the guidelines listed below will void the warranty and/or render the M9 sterilizer unsafe for operation. In the event of a malfunction, do not attempt to operate the sterilizer until necessary repairs have.

- Jan 14, 2020 The C983 Error Code may occur in some Ritter autoclave models of the Mismark M9 and M11 range. In order to fix this problem, you need to first understand the normal.

Midmark Error: E003

Error code E003 is an indication that the On/Standby got pressed during a cycle. Make sure none of your staff touches the On/Standby button during a cycle. If you are getting an E003 with nothing touching the On/Standby button it is possible you have a faulty display board that may need replacing.

Midmark Error: E004

Error code E004 is an indication that the door is ajar during the cycle. Make sure the door is fully closed and the door latch is pushed all the way down so that the door pin engages the door switch. After ensuring that the door is fully closed and latched and E004 is still happening it is possible you have a faulty door switch or the mechanism that engages it need realigned, send it in for service so that this problem can be repaired.

Midmark Error: E005

Error E005 indicates that the pressure exceeded 35 PSI during the cycle. Make sure the sterilizer is not overloaded and try running another cycle. If the Error E005 persists, it is possible you have a faulty steam trap, air bellows or out of calibration and the unit will need to be sent in for service.

Midmark Error: E006

Error E006 happens when the internal temperature exceeds 277 during the cycle. Make sure the unit is not getting overloaded. If you continue to experience the error after running additional cycles it is likely the unit is out of calibration, has a faulty temperature sensor and will need to be sent in for service.

Midmark Error: E007

Error E007 is an indication that there is low pressure during the cycle. The unit is likely losing steam, try checking the unit’s door gasket to make sure that it is not leaking steam and replace it if this is the case. Most of the time this error is caused by an internal steam leak like a backfill or vent valve, the steam trap of bellows or the unit needs to be recalibrated.

Midmark Error: E008

Error E008 means the door did not open at the end of the cycle. The good news is that your instruments likely got sterilized however the error occurred at the end of the sterilization cycle preventing it from going into the dry cycle. This error is more common with older units after years of wear the door pins and latch mechanism wear out and deform causing this to be an ongoing problem. There are a few fixes your repair specialist should be able to try, but if the problem continues perhaps it is time for a new unit.

Midmark Error: E009

Error E009 indicates that there is pressure buildup during the dry cycle. The good news is that your instruments likely got sterilized however the dry cycle did not complete. It is possible that your units 0 calibration is off, or the door is not fully opening at the end of the cycle due to broken door springs or a faulty door mechanism. You would like to need a service specialist to take a look at this issue for you.

Midmark Errors: E010, E011 & E012

Error E010, E011 & E012 are all software issues. Try rebooting the machine by unplugging it for 30 seconds. If this does not work, you likely need a new PC board which will have to be replaced and re-calibrated by a service professional.

by: dewi susanti

ritter autoclave

The C983 Error Code may occur in some Ritter autoclave models of the Mismark M9 and M11 range. In order to fix this problem, you need to first understand the normal working mechanism of this sterilizer.

While working properly, the Main PC Board within the autoclave is supplied with power that passes through two high-limit thermostats. These thermostats are normally “closed” (being “closed” means that the thermostat is in good working condition – it is defective when it is in the “open” state).

If one or both thermostats opens (maybe due to overheating or malfunction) the C983 error code occurs. Since the thermostat circuit powers nearly all other components, the sterilizer will completely shut down.

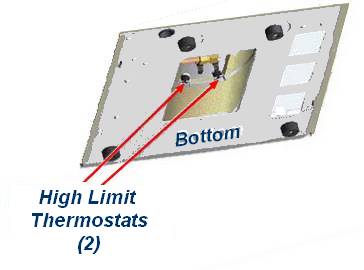

Locating The High Limit Thermostat

To fix a malfunctioning Ritter autoclave, the thermostat must first be located. It is placed on the lower part of the sterilizer chamber. In order to get to it, drain all the water within the reservoir, then lay the Ritter autoclave on its side with the door closed. This way, you can easily locate a small access panel at the bottom. The thermostats are right beneath this access panel.

Identifying The Bad Thermostat

Once you find the thermostats, you now need to identify the defective one. This can be done through a “continuity” test using a Multimeter or volt/Ohmmeter. The setting needed for this test may be found in the meter’s “ohm” section. It is normally 2k or 200. Take note that this test should only be carried out when the thermostats have cooled down to room temperature.

Begin by testing one thermostat then the other. Make sure to tag each of the connecting pair of wires in order to recall where each wire goes, before removing them from the thermostat. Place the proper setting on the meter, then apply a probe to contact each of the thermostat’s terminals.

If the meter reads either 0 or a value close to 0, it indicates that there is continuity. This means that the high limit thermostat being tested is in good working condition. On the other hand, if the meter reads 1, then the thermostat being tested is defective. Always test both of the thermostats even if you find the first one to be defective.

In the case that only one of the pair of high limit thermostats is defective, only that one should be replaced, while the other one remains. However, if both thermostats do register good meter readings, the two thermostats must be replaced.

The reason for this is because either one or both supposedly good thermostats is breaking connection at a low temperature (thermostats are factory set to stop electricity flow by breaking contact only at a high temperature – generally 4500F); otherwise the Ritter autoclave would not indicate the error code C983. In order to determine the defective thermostat in such a case you require more specialized techniques. Hence, it would be faster and less tasking to simply replace both high limit thermostats.

Once the thermostats have been replaced, make sure to re-attach all autoclave parts in the proper format. Making any errors in re-attaching critical circuitry components on the Ritter autoclave might create further malfunction.

Error Code Icegate

Incoming search terms:

Error Code 80070241 Windows 8.1

Error Code Mp145

- nu vot